About Us

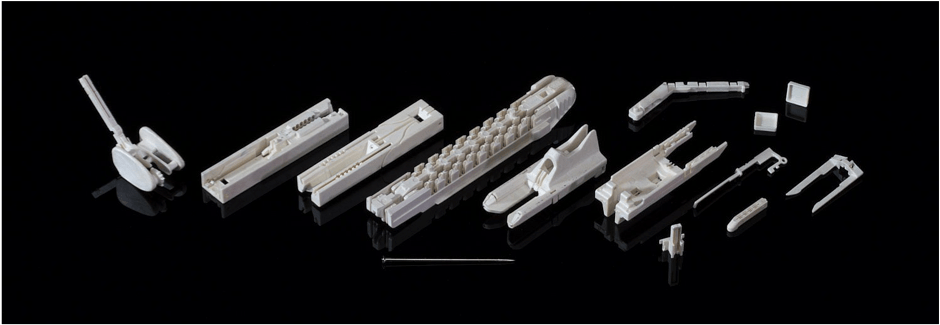

Injection Molding, Moldmaking & Asssembly with Surgical Precision

Matrix Plastic Products, located just outside of Chicago, Illinois, is a world leader in plastic injection molding, moldmaking, and manufacturing of precision products for the medical device, electronics, personal care and other high performance industries.

Matrix Plastic Products, located just outside of Chicago, Illinois, is a world leader in plastic injection molding, moldmaking, and manufacturing of precision products for the medical device, electronics, personal care and other high performance industries.

In 2026, Matrix Plastic Products is expanding our 3-shift operation from our current location in Wood Dale to an 88,000 square-foot facility in nearby Bloomingdale, to offer more manufacturing capacity and expanded services to global medical device customers. We're conveniently located just west of Chicago's O'Hare International Airport and we employ 140 talented team members.

In the Beginning

Matrix Plastic Products began operations in 1978 as Matrix Tooling. We started with seven employees and a rich family tradition of moldmaking craftsmanship. As our business grew based upon customer referrals, our reputation for precision, flexibility, and responsiveness allowed us to expand into injection molding in 1994.

By 2000 we were running volume molding production in a facility that had doubled in size. Our state-of-the-art quality inspection lab and ISO Class 8 cleanroom further enhanced our capabilities to serve our customers.

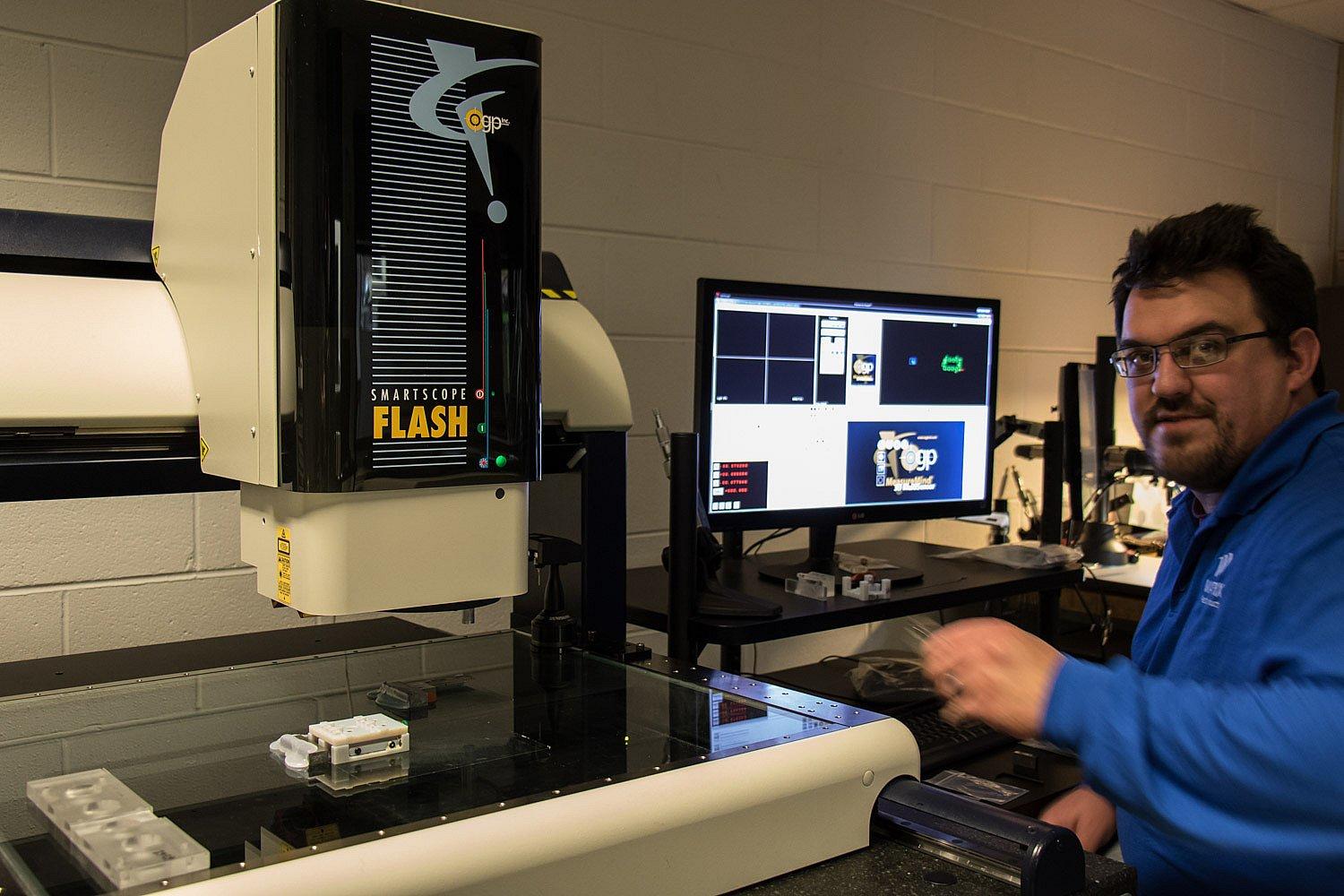

State-of-the-Art Quality Inspection Lab

Our advanced metrology laboratory features the latest in vision, touch probe, and laser inspection technology, giving us accurate data quickly and efficiently.

"Matrix is easily considered our best supplier. They continuously offer the highest quality molding and take great pride in their work. Their quality department is second to none and offers us more services than any other supplier. The relationship is more of a partnership on the product than just a service provided."

– Y.L., R&D Engineer,

Medical Device Customer

Our Quality Policy

We continually monitor the effectiveness of our quality management system (QMS) through internal audits, management reviews, and customer feedback. We are fully committed to continual improvement and exceeding our customers' expectations.

We continually monitor the effectiveness of our quality management system (QMS) through internal audits, management reviews, and customer feedback. We are fully committed to continual improvement and exceeding our customers' expectations.

Our Quality Policy states:

Matrix Plastic Products combines traditional craftsmanship, technical expertise, state-of-the-art technology, and GMPs to manufacture high precision plastic injection molded components and mold tooling.

We will continue to meet our customers’ expectations and support their compliance with regulatory requirements by continually improving our processes, procedures and employee training, thereby ensuring consistent quality in our products and services while maintaining our QMS.

We have incorporated the additional documentation, risk analysis, and recordkeeping requirements of ISO 13485:2016 into our QMS for the manufacturing, inspection and validation of medical device components.

Why ISO 13485?

Although Matrix is not a “specifications developer” of medical devices, our design engineers are often involved with our customers’ groundbreaking devices during the development stages. Our customers often designate us as a critical supplier on their projects, so we modeled our quality management system to comply with the ISO 13485:2016 standard for medical devices. We are equipped to provide full traceability and device history quality records to meet applicable regulatory requirements.

Why Choose Matrix Plastic Products?

When you choose Matrix Plastic Products to handle your project, you benefit from our core competencies:

45+ Years of Experience

Matrix Plastic Products has been designing and manufacturing the finest plastic injection molds and molded parts since 1978 in a very competitive market. Our engineers and designers average more than 30 years of experience in the industry, which translates to enhanced manufacturability, risk mitigation, and control of your project's total costs of ownership over the long term.

Matrix is proud of the talented employees we have working in each critical area: design, manufacturing and quality assurance. Highly skilled designers, toolmakers, process engineers and inspectors handle your project from start to finish, ensuring optimal results.

Continuous Investment in the Latest Technology

Matrix works hard to continually blend our experienced craftsmanship with the latest in manufacturing and inspection technology. We deliver top quality products, while constantly improving our processes and maintaining our competitive edge.

Enhanced automation allows Matrix to lower labor costs, match quick turnaround requirements, and provide advanced services that can't be performed manually. Our commitment to technology extends to every department, from design through inspection.

Unwavering Commitment to Quality

Our commitment to quality means that you'll get consistently positive results.

Higher quality processes result in lower maintenance, longer-lasting tools, and lower total costs of ownership over the lifetime of your project. We have maintained an ISO 9001 certified QMS since 1999. In 2010, we adapted our QMS to also become certified to ISO 13485, given our heavy focus on the medical device industry.

Reliability and Responsiveness

Paul Ziegenhorn, President Emeritus, Matrix Plastic ProductsMatrix Plastic Products successfully integrates an approachable, small-business atmosphere with the capabilities and sophistication of a larger company.

Paul Ziegenhorn, President Emeritus, Matrix Plastic ProductsMatrix Plastic Products successfully integrates an approachable, small-business atmosphere with the capabilities and sophistication of a larger company.

Reliability and responsiveness are among the highest grades we receive on our customer surveys.

Our customers can communicate directly with all project team members for technical clarification and progress updates.

Key team members handle your project from start to finish, and internal communication between departments ensures that everyone is kept informed as your project moves along smoothly.

Our primary goals are to deliver top-quality products and provide the caliber of service that builds long-term, mutually beneficial relationships with our customers.

"Matrix offers a strong blend of talent, new technology, and responsiveness... something that is becoming a rare find in manufacturing today." – Paul Ziegenhorn, President Emeritus and Co-Founder

Learn More

Take a virtual tour of Matrix Plastic Products to learn more about us and our capabilities.

Click the video to the right for a quick inside look at our engineering, moldmaking, molding, and inspection capabilities.

Then fill out the inquiry form or give us a call to see how we can make a difference in your operations and your bottom line.

_horizontal_white_536x129.png)